Current location:Home - Product Center - Activated carbon desulfurizer - GXT-1 Modified Activated Carbon Desulphurizer

Current location:Home - Product Center - Activated carbon desulfurizer - GXT-1 Modified Activated Carbon Desulphurizer

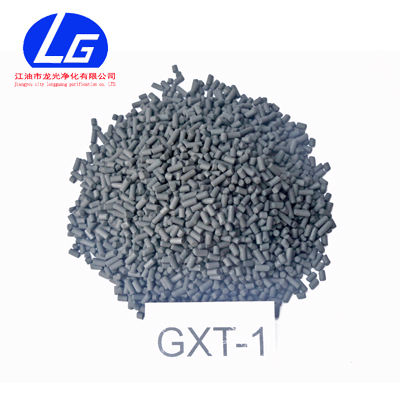

- GXT-1 Modified Activated Carbon Desulphurizer

-

GXT-1 modified activated carbon desulphurizer, with coal, coconut shells or wood as raw materials, is produced through carbonization after forming by extrusion of coke acting as adhesive, through activation by steam, and through screening; and is a modified activated carbon desulphurizer for fine desulphurization. After impregnation with active metallic solutions, etc., drying, calcination and screening, the product is thus obtained. This method features large sulfur capacity, high adaptability, low operation temperature, and the advantages that the desulfuriser can regenerate, be used repeatedly, work under normal temperature and pressure or pressurized condition, and that the sulfur can be recovered. The use of the desulfurizer is characterized by simple equipment, convenient to operate, large sulfur capacity, high purification rate, high adaptability, etc. The product is widely used for removal of H2S, organic sulfur and non-organic sulfur in natural gas, CNG natural gas, coal gas, coke oven gas, shift gas, food dioxide, carbon dioxide regas, petroleum refinery gas, biogas and other gases, and It is the highest quality product on the domestic market currently.

Parameters:

Product parameters | |||||

Product name | MODEL | Name of Project | Unit | Indicator | Remark |

Modified activated carbon defulfurizer | GXT-1 | color | black | ||

Spec. | Mesh | 100 | |||

Bulk density | kg/L | 0.5~0.65 | |||

Specific surface area | m2/g | 1000~1200 | |||

Pore volume | mL/g | 0.5~0.6 | |||

Working sulfur capacity | ﹪ | ≥20 | Aerobic environment | ||

breakthrough sulfur capacity | ﹪ | ≥25 | Aerobic environment | ||

Removal rate of hydrogen sulfide | ﹪ | >95 | |||

Working conditions

Temperature: Normal, preferable at 20-40℃.

Air speed: (1)Normal pressure: 200 -500 hour-1

(2) Pressurized: 500-1000 hour-1

Pressure: Normal pressure to 5 MPa

Height to diameter ratio: 3 or larger

Purified gas: Allowable H2S content is 5000mgs/Nm3. If higher desulfurization rate is required, multi-stage desulfurization can be employed

Water content: The water content acts as media in desulfurization, but too dry or too wet material may affect the efficiency of desulfurization. It is required that the moisture content in the gas should not exceed the saturated moisture content at operation temperature. The liquid carried in the process charge gas should be avoided to prevent the micropores of the desulfurizer from being blocked and its strength from being damaged greatly.

PH value: Keeping the desulfurizer at PH8- 9 is helpful for desulfurization.

Defulfurization Mechanism

The desulfurization mechanism of activated carbon is to accelerate the process of the following reaction of the H2S and O2 in the gas by the catalytic effect of the surface activity nature of activated carbon:

2H2S+O2------2H2O+2S ΔH=-434.3kJ/mol

Actually, the reaction between H2S and O2 on the surface of activated carbon is carried out in two steps: First, the activated carbon absorbs oxygen at its surface to form activated oxides on the surface; then the H2S molecules in the gases react with the adsorbed oxygen to produce sulfur, which is deposited on micropores of the activated carbon. To accelerate the reaction and improve the desulfurization efficiency, the actual ratio of O2/H2S should be larger than the theoretical value of 0.5, and the preferable value of the ratio is 3.

Active metals such as copper, alkali metals and alkaline earth metals can be introduced into the activated carbon desulfurizer by impregnation to make the activated carbon modified and its catalyzing efficiency improved.

Sales hot-line:0816-3736605

Sales hot-line:0816-3736605 E-mail:jysongwei@126.com

E-mail:jysongwei@126.com Address:No. 772, Laojun Road, Jiangyou, Sichuan

Address:No. 772, Laojun Road, Jiangyou, Sichuan

QQ

QQ Tel

Tel Message

Message Share

Share Top

Top