Current location:Home - Product Center - Iron oxide desulfurizer - ZDE-01 Type Iron Oxide Desulfurizer

Current location:Home - Product Center - Iron oxide desulfurizer - ZDE-01 Type Iron Oxide Desulfurizer

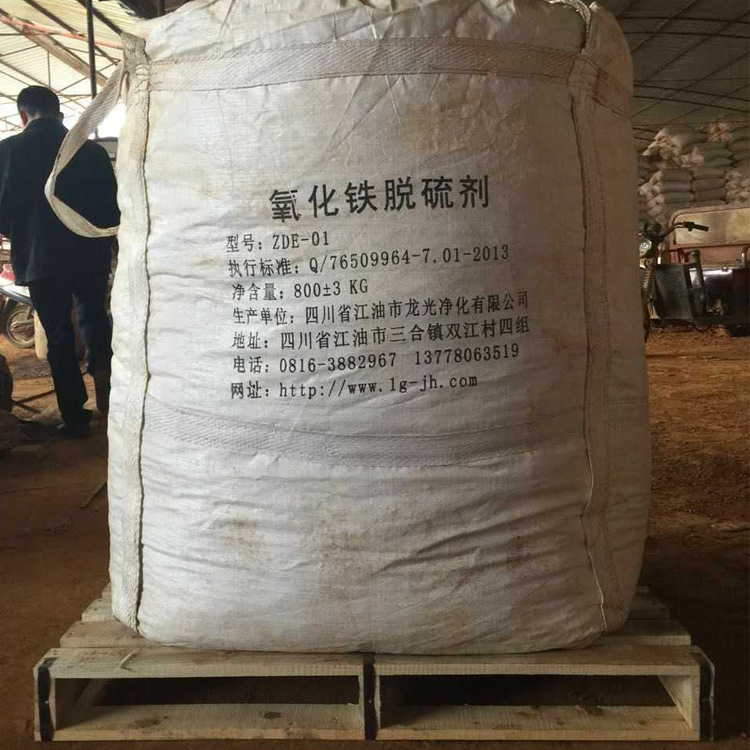

- ZDE-01 Type Iron Oxide Desulfurizer

-

The ZDE series of solid iron oxide desulfurizer, produced by Sichuan Jiangyou Longguang Purification Co., Ltd., is made mainly from active Fe2O3, supplemented with a variety of additives. The ZDE type normal temperature iron oxide desulfurizer is a new type of highly adaptable and effective gas desulfurizer used at normal temperature by dry means, and can work under normal temperature conditions. It is of simplicity in equipment, easiness in operation, high sulfur absorption capacity and purification degree, strong adaptability, etc. during use. It can widely be applied to desulfuration of natural gas and coal gas furnaces, and H2S removal in CNG natural gas, coal gas, coking furnace gas, shift gas, food carbon dioxide, carbon dioxide regeneration gas, petroleum refined gas, biogas and other gas, and it can also dismiss organic sulfur up to a point. The ZDE series of products is the best in quality at present, and has been highly favored by new and old customers for a long time.

Parameters for the ZDE-01 type iron oxide desulfurizer

ZDE-01 type iron oxide desulfurizer | |||

Item | Unit of Measurement | Indicator | Remark |

color | Yellow | ||

Granularity | mm | Φ(4.5~6)×L(5~15)mm | |

Loading Density | kg/l | 0.7~0.85 | |

Pore volume | mvg | ~0.4 | |

Lateral pressure strength | % | >45 | |

Working sulfur capacity | % | 25 | Constituents with oxygen |

15 | Constituents without oxygen | ||

Moisture | % | ≤10 | |

Desulfurization accuracy | ppm | ≤1 | |

Service conditions:

Temperature: normal, preferable at 20-40℃

Air speed: (1) Normal pressure: 200 -500 hours-1

(2) Pressurization: 500-1000 hours-1

Pressure: from normal pressure to 3 MPa

Ratio of height to diameter: 3:1

Gas to be purified: H2S content of up to 5000 mgs/Nm3 is allowed. If high desulfurization accuracy is required, multi-level desulfurization shall be adopted.

Water content: The water content acts as media in desulfurization, but too dry or too wet material may affect the efficiency of desulfurization. It is required that the moisture content in the gas should not exceed the saturated moisture content at operation temperature. The liquid carried in the process charge gas should be avoided to prevent the micropores of the desulfurizer from being blocked and its strength from being damaged greatly.

PH value: the PH value of the desulfurizer shall be kept at PH8 ~ 9 in favor of desulfurization.

Regeneration: temperature: 30 to 60°C with a maximum of 80°C.

Sales hot-line:0816-3736605

Sales hot-line:0816-3736605 E-mail:jysongwei@126.com

E-mail:jysongwei@126.com Address:No. 772, Laojun Road, Jiangyou, Sichuan

Address:No. 772, Laojun Road, Jiangyou, Sichuan

QQ

QQ Tel

Tel Message

Message Share

Share Top

Top